Custom Built Systems

Enerzi specializes in building state of the art Microwave Heating systems for specific applications as can be seen from the product-line. However, we at Enerzi thoroughly understand that Microwave heating is a recent technology and offers a great hope to develop numerous products for a variety of applications. Hence we have been passionately working on new ideas and concepts with technology support from various research organizations. Some of the key systems we have developed are ;

Microwave Polymer Curing Ovens – Microven

The application of microwave heating to polymers and polymeric composites has been pursued worldwide over the past three decades.Microwave processing offers many advantages over conventional thermal processing. Rapid volumetric heating in microwave processing would significantly reduce cycle times and additionally, since power is applied directly to the material, the need to heat processing equipment is avoided and energy requirements are further reduced. Microwave Curing Ovens are fast making their way into industries and replacing the conventional ovens like electrical ovens and gas/oil fired ovens. Typical applications in Industry include Resin Bonded Abrasives and Composites used in Aerospace industry.

The application of microwave heating to polymers and polymeric composites has been pursued worldwide over the past three decades.Microwave processing offers many advantages over conventional thermal processing. Rapid volumetric heating in microwave processing would significantly reduce cycle times and additionally, since power is applied directly to the material, the need to heat processing equipment is avoided and energy requirements are further reduced. Microwave Curing Ovens are fast making their way into industries and replacing the conventional ovens like electrical ovens and gas/oil fired ovens. Typical applications in Industry include Resin Bonded Abrasives and Composites used in Aerospace industry.

Enerzi offers two important variants of Microwave Polymer Composite Curing Ovens viz. Batch and Conveyor systems.

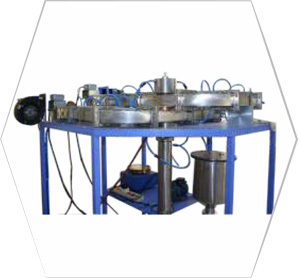

Microwave Chemical Synthesis Ovens

Microwave Chemical Synthesis is the process of applying microwave radiation to chemical reactions to synthesize new chemicals. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric dipoles/charges such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy in collisions. Semiconducting and conducting samples heat when ions or charges within them form an electric current and energy is lost due to the electrical resistance of the material. Microwave heating in the laboratory began to gain wide acceptance following papers in 1990s.

Microwave Chemical Synthesis is the process of applying microwave radiation to chemical reactions to synthesize new chemicals. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric dipoles/charges such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy in collisions. Semiconducting and conducting samples heat when ions or charges within them form an electric current and energy is lost due to the electrical resistance of the material. Microwave heating in the laboratory began to gain wide acceptance following papers in 1990s.

Conventional heating usually involves the use of a oven or oil bath, which heats the walls of the reactor by convection or conduction. The core of the sample takes much longer to achieve the target temperature, especially when the substance is a solid.

Microwave heating is able to heat the target compounds without heating the entire furnace or oil bath, which saves time and energy. It is also able to heat sufficiently thin objects throughout their volume (instead of through its outer surface), in theory producing more uniform heating. However, due to the design of most microwave ovens and to uneven absorption by the object being heated, the microwave field is usually non-uniform and localized superheating might occur. To counter this limitation often some kind of agitation arrangement is used; either to agitate the field or to agitate the compound as demanded by the process.

Microwave heating can have several benefits over conventional ovens:

- Reaction rate acceleration

- Higher yieldn

- Lower energy usagen

- Different reaction selectivenessn

Enerzi offers a specially designed Microwave Chemical Synthesis Oven for research and production alike.

The application of microwave heating to polymers and polymeric composites has been pursued worldwide over the past three decades.Microwave processing offers many advantages over conventional thermal processing. Rapid volumetric heating in microwave processing would significantly reduce cycle times and additionally, since power is applied directly to the material, the need to heat processing equipment is avoided and energy requirements are further reduced. Microwave Curing Ovens are fast making their way into industries and replacing the conventional ovens like electrical ovens and gas/oil fired ovens. Typical applications in Industry include Resin Bonded Abrasives and Composites used in Aerospace industry.

The application of microwave heating to polymers and polymeric composites has been pursued worldwide over the past three decades.Microwave processing offers many advantages over conventional thermal processing. Rapid volumetric heating in microwave processing would significantly reduce cycle times and additionally, since power is applied directly to the material, the need to heat processing equipment is avoided and energy requirements are further reduced. Microwave Curing Ovens are fast making their way into industries and replacing the conventional ovens like electrical ovens and gas/oil fired ovens. Typical applications in Industry include Resin Bonded Abrasives and Composites used in Aerospace industry. Microwave Chemical Synthesis is the process of applying microwave radiation to chemical reactions to synthesize new chemicals. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric dipoles/charges such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy in collisions. Semiconducting and conducting samples heat when ions or charges within them form an electric current and energy is lost due to the electrical resistance of the material. Microwave heating in the laboratory began to gain wide acceptance following papers in 1990s.

Microwave Chemical Synthesis is the process of applying microwave radiation to chemical reactions to synthesize new chemicals. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric dipoles/charges such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy in collisions. Semiconducting and conducting samples heat when ions or charges within them form an electric current and energy is lost due to the electrical resistance of the material. Microwave heating in the laboratory began to gain wide acceptance following papers in 1990s.