Rubber Vulcanization Ovens

Vulcanization is a chemical process for converting rubber or related polymers into more durable materials through the addition of sulfur or other equivalent “curatives.” These additives modify the polymer by forming crosslinks (bridges) between individual polymer chains. Vulcanized materials are less sticky and have superior mechanical properties. A vast array of products is made with vulcanized rubber including tires, automotive weather strips, sealings, shoe soles, hoses, and hockey pucks. The process is named after Vulcan, the Roman God of Fire.

Uncured Natural Rubber is sticky, deforms easily when warm, and is brittle when cold and hence is very poor in elasticity. The reason for inelastic deformation of un-vulcanized rubber can be found in its chemical structure. Rubber is composed of long polymer chains. These chains can move independently relative to each other, which lets the material change shape. Crosslinking introduced by vulcanization prevents the polymer chains from moving independently. As a result, when stress is applied the vulcanized rubber deforms, but upon release of the stress, it reverts to its original shape.

Microwave Vulcanization Ovens – Microven

Rubber vulcanization has been a vastly popular application of Microwave Heating. The Bulk heating property of Microwaves combined with the rapid heating phenomenon makes Microwave Heating an ideal choice for rubber and rubber like materials. Rubber being a bad conductor of heat, any method of heating rubber relying on the conductivity of it scores a point lower compared to Microwave heating because Microwaves penetrate the rubber and heat the material from core to surface simultaneously. Most common and widely proven application of Microwave Heating is for the vulcanization of Automotive and Construction rubber profiles. Microwave Heating has been proven to be equally suited for Sponge, Solid and Co-extruded profiles. Since this is one of the well proven applications, there is rarely a need for any labscale or prototypes. Enerzi offers a range of Continuous Microwave Rubber vulcanization ovens for a range of rubber profiles.

Salient Features

- Throughput of 50 to 500 kg/hour

- Hot Air Circulation of 100 to 1000 cfm

- Typical cross section of 250 mm (W) x 200 mm (H)

- Maximum Process Temperature from 100 to 400 deg. C

- Hot Air Temperature Control from 200 to 300 deg. C

- Installed Microwave Power of 1.45 kW to 29 kW

- Step-less Power Control using Microcontroller Module

- Digital display of Power and Temperature

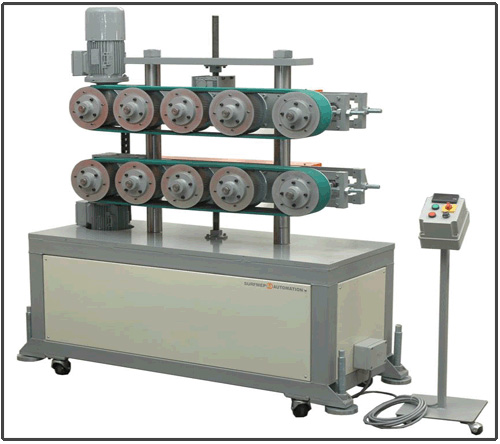

- Conveying System with speed controls from 2 to 50 m/min

- Highly Integrated Interlocks with a Remote Control Panelv